Our versatility relies on our large diversity of equipment : CNC fixed and sliding headstock lathes, secondary operation lathes, machining centers, allowing us to produce any kind of parts, for every branch of industry.

OUR KNOW-HOW

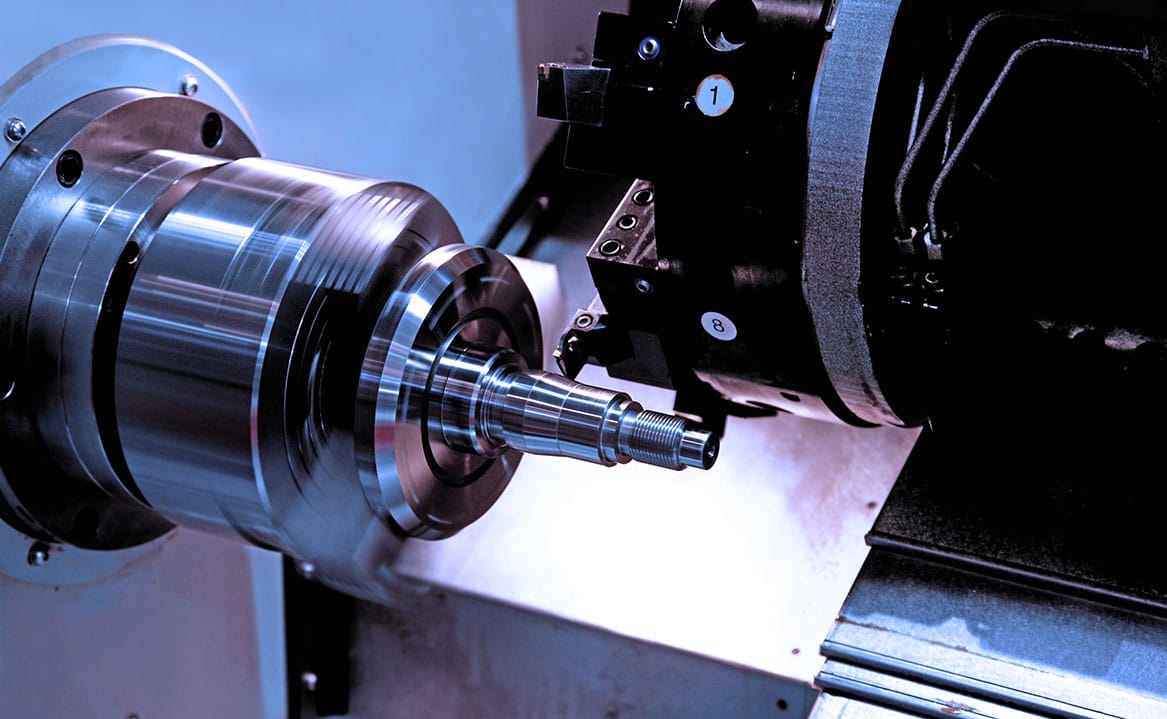

MACHINING – SCREW-MACHINING

MAZAC INTEGREX 400 T (tour fraiseur 5 axes)

New generation, high-performance lathe, its carries out high added-value technical parts whilst being eco-friendly and energy efficient. It needs accurate settings that require the presence of skillful professionals. The raw material machined are multiple : steel, unalloyed steel, brass, aluminum.

CNC SLIDING HEADSTOCK LATHE

Our automatic sliding head lathes are fitted with several axes so as parts can be machined simultaneously using different tools at the same time. As a result, cycle times can be dramatically reduced. Each machine is equipped with a swarf conveyor and an automatic bar feeder. Our lathes have a bar capacity from 2 to 42 mm. They are fast and accurate, easy to operate, 99 % of the parts are finished on machine.

- CITIZEN L20-VIII bar capacity 20 mm

- CITIZEN K16 bar capacity 16 mm

- CITIZEN M32 bar capacity 32 mm

- MANURHIN KMX : bar capacity 26 mm

- STAR : SB16 – SR10 – SR20 – SR32 – SV32 – ST38

CNC FIXED HEADSTOCK LATHE

Our CNC fixed headstock lathes are fitted with a swarf conveyor and an automatic bar feeder. They are used to machine parts with elaborate geometric design made in steel, stainless steel, high strength brass, plastics like bearings, nuts, electrodes, injector vessel… intended for multiple branches of industry such as shipbuilding, car and trucks, healthcare devices

Our lathes are able to work round and hexagonal bars from 8 to 80 mm and tubes.

- 1 BIGLIA bar capacity 38 mm

- 1 BIGLIA bar capacity 70 mm

- 1 BIGLIA bar capacity 80 mm

- 1 BND 42 : bar capacity 42 mm

- HAAS : bar capacity 80 mm

- 2 OKUMA LT10M : bar capacity 42 mm with C axis

- OKUMA LCC152S : bi-turret – 50 mm

Discover our company through its history

Our DNA is defined by our history, it is thanks to our values that we support you in the success of your project.

Since 1989 SDM bar turning and machining shares its experience

In order to respond to the most complex requests, our know-how has enabled us to specialize in specific sectors of activity.

REWORKING AND FINISHING EQUIPMENT

Some parts need to be reworked or finished on specific lathes. Our factory has its own reworking workshop made up of several machines allowing secondary or finishing operations.

- Transfer units

- 3 CNC turning centers

- Tapping machines

- Trapezoidal tapping machine

- Reworking machine TAKAMAZ with automatic loading robot

- Press machine

- 4 lathes with 2 axis (used for slugs working)

- Mechanical lathes for various reworking operations : deburring, brushing…

OTHER COMPLEMENTARY OPERATIONS

Our wokshop and our equipment allow us to propose additional services like assembly (with an area specifically arranged for the assembly of mass-market products) ; marking, bending, etc… We also have our own sawing machine used for slug parts.